strain hardening & rockwell hardness test on metallic specimen|strain hardening vs work hardening : ODM Before work hardening, the lattice of the material exhibits a regular, nearly defect-free pattern (almost no dislocations). The defect-free lattice . See more Resultado da Home | Slots Casino Games | Live Casino | | Promotions. Play the most exciting online casino games at 777 - wide selection of slots, jackpots, .

{plog:ftitle_list}

Resultado da OnTorrent - O melhor site para Baixar/Fazer Download de Filmes Torrent e Series Torrent do Brasil, entre e Baixe agora mesmo Totalmente Grátis!

what is strain hardening coefficient

Work hardening, also known as strain hardening, is the process by which a material's load-bearing capacity (strength) increases during plastic (permanent) deformation. This characteristic is what sets ductile materials apart from brittle materials. Work hardening may be desirable, undesirable, or inconsequential, . See more

An example of undesirable work hardening is during machining when early passes of a cutter inadvertently work-harden the workpiece surface, causing damage to the cutter during the later passes. Certain alloys are more . See moreBefore work hardening, the lattice of the material exhibits a regular, nearly defect-free pattern (almost no dislocations). The defect-free lattice . See moreThere are two common mathematical descriptions of the work hardening phenomenon. Hollomon's equation is a power law relationship between the stress and the amount of . See more

electric screwdriver test

strain hardening vs work hardening

An example of desirable work hardening is that which occurs in metalworking processes that intentionally induce plastic deformation to exact a shape change. These processes are known as cold working or cold forming processes. They are characterized . See more

SteelSteel is an important engineering material, used in many applications. Steel may be work hardened by . See moreStrain hardening is also called work-hardening or cold-working. It is called cold-working because the plastic deformation must occurs at a temperature low enough that atoms cannot rearrange . Strain hardening, also referred to as cold working or work hardening, is the process where metals are made stronger and harder through permanent deformation. Strain hardening is an effective strengthening process when many dislocations are created during plastic deformation. Dislocations are formed at grain boundaries, free .

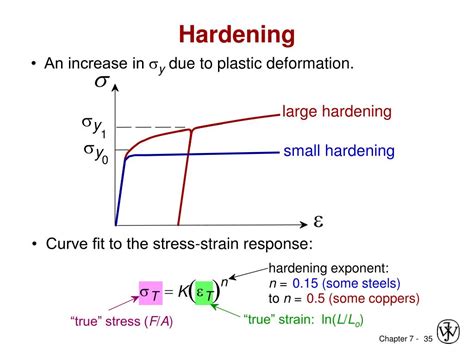

Strain Hardening is when a metal is strained beyond the yield point. An increasing stress is required to produce additional plastic deformation and the metal apparently becomes stronger and more difficult to deform. .

Work hardening, also known as strain hardening or cold working, is a phenomenon that occurs during the plastic deformation of metallic materials. Strain-hardening (the increase of flow stress with plastic strain) is the most important phenomenon in the mechanical behaviour of engineering alloys because it ensures that flow is. When metals are deformed plastically at temperatures lower than would cause recrystallization, they are said to be cold worked. Cold working increases the strength and hardness. The terms work hardening and strain .

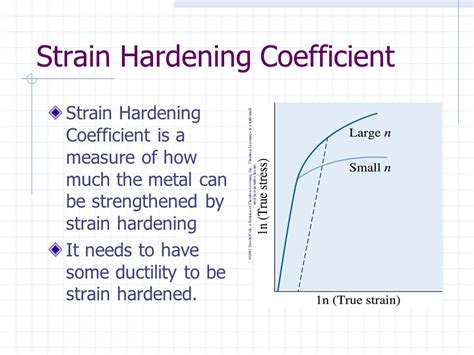

Second, the experimental mechanical properties of T6 laminate were higher than the results predicted by the ROM, suggesting the presence of additional strengthening and work . The rate of strain hardening is enhanced as well, as can be seen in the true stress-true strain curve (Supplementary Fig. 9). This is because, the dislocation lines fighting through Ni-enriched . For materials following the power law, the true strain at the Ultimate Tensile Strength is equal to n. when you plot the log-log plot, use data points after the yield point (to avoid elastic points) and before instability .

ecu tester tool

The strain hardening exponent (also called the strain hardening index), usually denoted , is a measured parameter that quantifies the ability of a material to become stronger due to strain hardening. Strain hardening (work hardening) is the process by which a material's load-bearing capacity increases during plastic (permanent) strain, or deformation.

在单轴拉伸试验中,当应力超过屈服强度后,需要施加更大的载荷产生更大的应力,才会使材料发生更多的塑性变形。随着塑性应变的增加,材料变得更强、更难以变形了,因此这个阶段称为“应变硬化”(Strain Hardening.

Strain hardening is one of the most-used means of adding strength to an alloy. It is the use of permanent deformation to increase the strength of the metal.

Determining the strain-hardening exponent (n) requires converting this equation to logarithmic form: log(σ) = log(K) + n*log (ɛ) (eq. 2) For metal alloys where the Holloman relationship accurately represents the flow curve, n-value is the slope of eq. 2, and K is the true stress at a true strain ɛ = 1. Nucleation refers to the appearance of a crystal and the beginning of its growth. The point where nucleation occurs, is called the nucleation point. At the solidification or freezing temperature, atoms of a liquid (e.g. molten metal) begin to bond together at the nucleation points and start to form crystals.Work Hardening and Annealing. R.E. Smallman, A.H.W. Ngan, in Modern Physical Metallurgy (Eighth Edition), 2014 Work hardening arises from the interactions of dislocations with amongst themselves or with other defects such as second-phase particles.Work ( Strain ) Hardening - Strength ( Mechanics ) of Materials. Strength / Mechanics of Materials Table of Content. Work hardening is when a metal is strained beyond the yield point.

Mathematical expression describing plastic behavior of steels allows the execution of parametric studies for many purposes. Various formulas have been developed to characterize stress strain curves of steels. However, most of those formulas failed to describe accurately the strain hardening behavior of steels in the full range which shows various distinct stages. For .The similarity of orientation dependence of yielding and strain-hardening rate in Ll 2 compounds suggests that they arise from a common mechanism, namely the increasing formation of Kear–Wilsdorf locks (arising from cross slip of leading screw dislocations from the primary {111} planes to planes of type {100}). This cross-slip mechanism has been suggested to occur in .

Surface mechanical treatment. Over the past two decades, three surface mechanical treatment methods have been developed to produce gradient nanostructures in a surface layer of bulk metallic .In the equation for stress, P is the load and A 0 is the original cross-sectional area of the test specimen. In the equation for strain, L is the current length of the specimen and L 0 is the original length. Stress-Strain Curve. The values of stress and strain determined from the tensile test can be plotted as a stress-strain curve, as shown below: As mentioned above, strain hardening is primarily caused by dislocation interaction, this is due to the fact that when two dislocations moving in different planes intersect each other, a kink is formed in the intersected dislocation line segment, as shown in Fig. 4.3.The dislocation kink has a Burgers vector different from the one of the original dislocation, so, in an .

Strain hardening, also called work hardening, is a property of crystalline materials much valued by engineers: under load, strong materials can become even stronger. For many years, strain .Strain hardening has been studied extensively, ever since its mechanism was first discussed in a very limited form by Taylor in his pioneering publication introducing the concept of a dislocation as a “plasticity carrier”.It is a very complex process and many aspects of it are still intensely debated.Strain energy. The area under the \(\sigma_e - \epsilon_e\) curve up to a given value of strain is the total mechanical energy per unit volume consumed by the material in straining it to that value. Advanced ultrahigh strength steels (UHSSs) with yield strength above 1.5 GPa are often required in the most challenging structural applications, such as sustainable manufacturing, mobility, energy and safety [1].The flagship class of UHSSs is the so-called maraging steels which usually contain a high density of nanoprecipitates (NPs) after tempering of a supersaturated .

Subject - Material TechnologyVideo Name - Strain HardeningChapter - Strain HardeningFaculty - Prof. K Krishna KishoreUpskill and get Placements with Ekeeda . Mechanical properties. Figure 4a,b show the true stress–strain curves of the aged alloys and corresponding strain hardening rate curves measured at 293 °C respectively. Even after aging at 600 .

Improvement of strain hardening in modified duplex lightweight steel. Figure 2(a,b) shows EBSD phase maps of the previous and modified steels after the 66%-cold-rolling followed by annealing at .

In this chapter we will discuss three main topics: cold working, by which a metal is simultaneously deformed and strengthened; hot working, by which a metal is deformed at high temperatures without strengthening; and annealing, during which the effects of strengthening caused by cold working are eliminated or modified by heat treatment.The strengthening we obtain during cold . Measurements of the tensile true stress vs. true strain curves are the most common way to study the mechanical properties during plastic deformation [1,2,3].However, in a uniaxial tensile test, the true stress-strain curve can be calculated from an engineering stress-strain curve only within the uniform deformation region [], hence only a limited range of strain .

Strain hardening, also known as work hardening, is a process that strengthens metals by deforming them plastically, increasing their dislocation density and thereby enhancing resistance to further deformation.

I have come across the definition somewhere,"Work hardening, also known as strain hardening, is the strengthening of a metal or polymer by plastic deformation. This strengthening occurs because ofHardening is a metallurgical metalworking process used to increase the hardness of a metal. The hardness of a metal is directly proportional to the uniaxial yield stress at the location of the imposed strain. A harder metal will have a higher resistance to plastic deformation than . Over the years, empirical equations, such as Hollomon, Ludwik, and Ludwigson, have been used to describe strain hardening behavior of materials for engineering purposes.[] Subsequently, phenomenological models were developed based on the idea that flow stress at a given strain rate and temperature depends upon a parameter that describes the current .

CHAPTER 7 Strain Hardening and Annealing 7.1 Introduction 7.2 188 In this chapter we will discuss three main topics: cold working, by which a metal is simultaneously deformed and strengthened; hot working, by which a metal is deformed at high temperatures without strengthening; and annealing, during which the effects of strengthening caused by cold .

strain hardening vs cold working

Resultado da Disfruta de las mejores telenovelas, programas y deportes de Televisa, la empresa de medios en español líder del mundo. Mira los capítulos .

strain hardening & rockwell hardness test on metallic specimen|strain hardening vs work hardening